Why wood?

Wooden cutting boards have been incredibly popular for many years. Compared to plastic and glass options, they simply have this irresistible natural look. From the warm tones of cherry and walnut to the elegant nuances of maple and oak, wood effortlessly adds that natural touch to any kitchen.

But it’s not just about appearance – wooden cutting boards also feel great. Cutting ingredients on them is not only easy but also safe. And hey, it does your knife a favor every day. Even a hot pot can’t harm these boards.

The best part? With proper care, they last forever. If your knife ever cuts a bit too deep, you can easily restore the board to its former glory. Believe me, I’ve been exclusively using wooden cutting boards for years and that’s not going to change!

The pros and cons of using wood vs. plastic cutting boards

The decision of whether you prefer plastic or wood naturally depends on your personal preferences and needs. As someone who has an affinity for wood, the advantages of wooden cutting boards outweigh in terms of aesthetics, user-friendliness and environmental-friendliness. Additionally, crafting a wooden cutting board on your own can be a rewarding learning project where you can express and strengthen your love for the material wood.

Requirements for the best cutting board

When it comes to choosing best cutting board, there are certain requirements that you should keep in mind to ensure you get the best possible option for your kitchen and get the basics, how to make a cutting board! But before let`s answer the question: What is a good cutting board?

Material Quality

When it comes to assessing the quality of wood, experience is crucial. You either possess this knowledge or rely on a professional, preferably an experienced furniture builder. Wood is classified based on visible features such as knots, cracks, and grain patterns. The use of grade A furniture wood (Select or Clear) is particularly important in this regard. This means that wood in this grade has few to no knots or irregularities. It is free from defects and has a uniform color and grain. Additionally, our wood should be adequately dry for processing (with a wood moisture content between 10-12%) and we avoid using outer sapwood (porous and soft) as well as inner heartwood (hard and prone to cracks). Of course, choosing the right wood species is crucial, but after reading this article, that shouldn’t be a problem for you.

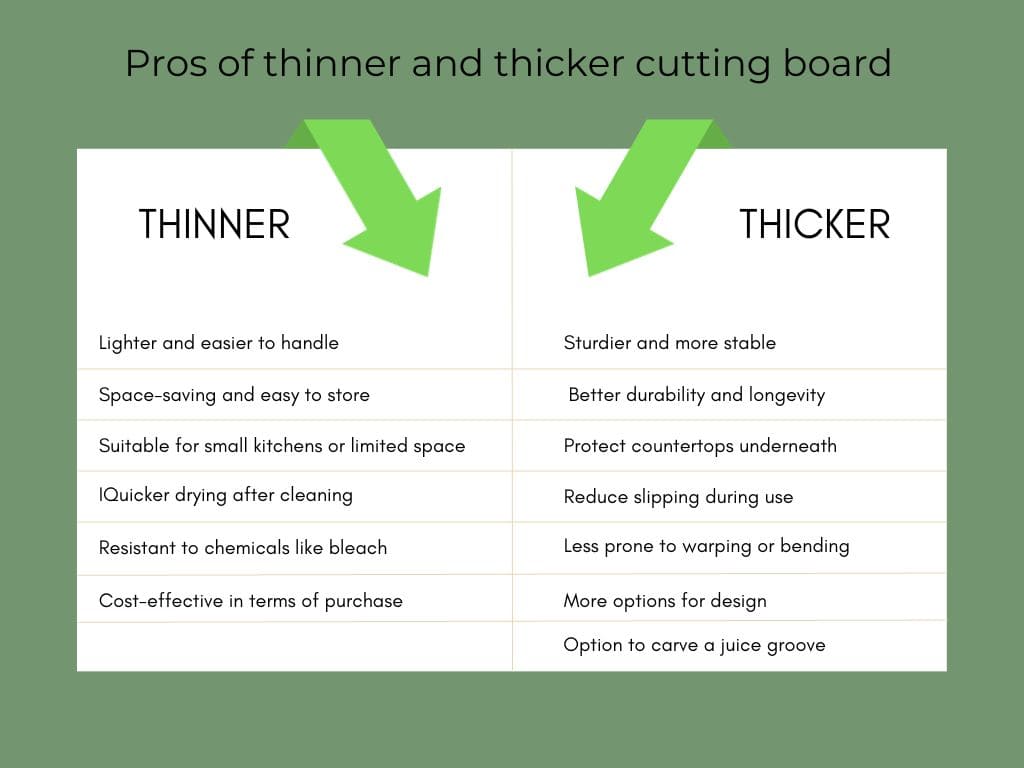

Cutting Board Thickness

Thicker wooden cutting boards, ranging from 35 (1.4″) to 50 (2″)mm in thickness, are the favorites among professional kitchen chefs and enthusiastic home cooks. Why? Because they provide a truly robust work surface where you can chop, cut and dice without the board significantly shifting or bending. Having used various cutting boards over the years, I can recommend the following: The thicker and heavier boards are perfect for a permanent spot in your kitchen for daily use (assuming you have enough space). Thinner cutting boards, around 18 (0.7″) to 25mm (1″) thick, are ideal for use as snack boards or for cutting vegetables like garlic and onions. When it comes to end-grain boards, I would suggest a thickness of at least 40mm (1.6″). Tip: When considering cutting board thickness, it’s generally better to opt for something thicker rather than thinner!

Size

The size of your cutting board is a personal matter and depends on factors like how much kitchen space you have, how convenient you want it to be, and what kind of cutting tasks you’ll be using it for. The beauty of DIY is that you can customize your cutting board to fit your needs. I don’t want to get into endless debates here, but I can give you some practical insights.

For a snack board, go for 30cm (11.8″) in length, 20cm (7.9″) in width and 2cm (0.8″) in thickness.

If you’re aiming for a small cutting board, consider 35cm (13.8″) in length, 25cm (9.8″) in width and 2.5cm (1″) in thickness.

If you want a stationary cutting board, you can go as big as 45cm (17.7″) in length, 35cm (13.8″) in width and min. of 3.5cm in thickness (for end grain, at least 4cm (1.6″))

But keep in mind that larger boards come with more weight and can be less convenient to handle. So, regular washing after use might require a bit more effort!

Weight & Stability

In general, the heavier your cutting board, the more stable and less prone to warping it is. The added weight also reduces the likelihood of it sliding around on your kitchen countertop, providing extra safety while you work. But you know what really makes a difference? Those little feet on the bottom of the board!

When using a cutting board in a stationary manner, you should never place it directly on the countertop. There are a couple of good reasons for this. First, it helps prevent slipping and second, it allows for some space underneath, promoting air circulation. This ensures that the underside of your cutting board stays nice and dry. You can use rubber feet for this purpose or opt for more elegant stainless steel or aluminum feet with rubber padding. A gap of 2cm (0.8 inches) between board and underground surface is entirely sufficient.

By the way, if you’re using a smaller, more mobile cutting board, placing a damp cloth underneath can help minimize slipping.

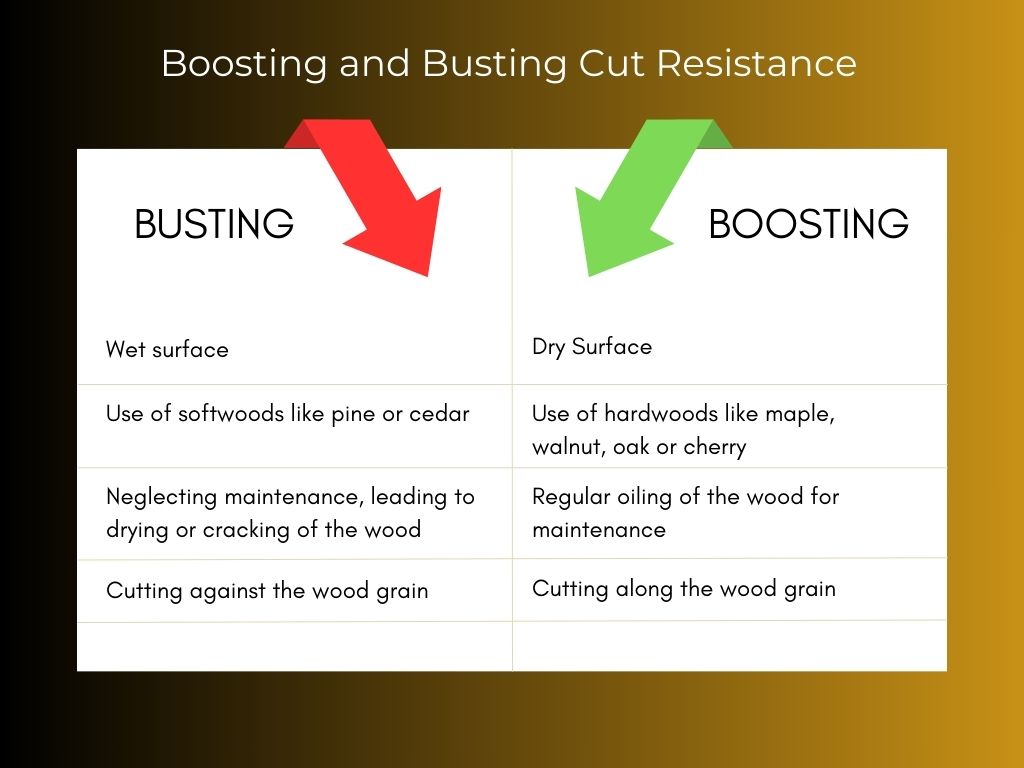

Cut resistance

Of course, you want a cutting board with excellent cut resistance to make it last longer and save you money in the long run. The good news is that with the right choice of wood, you can achieve fantastic results that outshine other materials.

The best cutting board should be designed to keep cut marks as shallow as possible while avoiding wood that’s too hard, as it can dull your knife blade. The type of wood and the way the board is constructed play a crucial role here. It makes a big difference whether you’re working on a cutting board where the wood fibers run across (edge-grain board) or parallel to the surface (end-grain board).

Naturally, a high-quality cutting board does come at a slightly higher cost, whether in terms of crafting it yourself or purchasing one. Acquiring premium woods like walnut, maple or oak can be expensive and the more intricate construction of end-grain boards involves additional steps that affect the price.

However, as with many things in life, this investment pays off. A high-quality, cut-resistant cutting board can serve you faithfully for decades!

Odor neutrality

Naturally, you want a cutting board that not only provides a stable and durable surface for slicing but also doesn’t absorb unpleasant odors from the food you prepare. Odors tend to develop in areas where liquids can penetrate the wood’s pores. So, it’s already clear which factors can improve the odor neutrality of the cutting board.

A good choice is hardwood, as it has a tight grain structure and lower porosity, meaning it absorbs fewer odors. However, even with hardwood, regular cleaning and maintenance are crucial. This includes periodic treatment with the right oil or wax.

Another helpful measure is using separate cutting boards for specific foods like onions, garlic or fish. If unpleasant odors still occur, you can follow these steps:

- Thoroughly moisten the cutting board with water.

- Sprinkle a generous amount of salt on the cutting surface.

- Rub the salt in with a halved lemon.

- Let it sit briefly, then rinse the board thoroughly with water.

- Allow the cutting board to dry thoroughly.

This method should help eliminate unwanted odors and keep your cutting board fresh.

Appearance

Your best cutting board is going to be your trusty sidekick in the kitchen day in and day out, so why not make sure it’s not just functional but also downright good-looking? Every type of wood has its unique style and charm. But there’s one thing that’s always there with wood – its warm and natural touch that makes it beautiful and timeless, no matter which wood you go for.

- Cherry wood, for instance, shows off warm reddish-brown tones and a smooth grain pattern, giving it a refined look and a beautiful natural shine.

- Oak wood, on the other hand, impresses with its rustic appearance, ranging from rich browns to creamy whites, and eye-catching, distinctive grain patterns and streaks.

- European maple wood boasts a light, almost creamy texture with a straight grain pattern that exudes simplicity and elegance.

- American maple wood, in contrast, ranges from creamy white to light reddish-brown with a slightly wavy grain pattern.

- European walnut wood offers an elegant blend of deep, dark browns and refined, almost silky grain patterns that add a touch of luxury to any space.

- American black walnut stands out with its rich, dark to light brown shades and medium to coarse texture. When treated with oils or waxes, it reveals its bold and fiery character.

- Beechwood, with its reddish-brown color, characteristic wood rays, and fine, consistent texture, has its unique appeal.

- Teak wood captivates with its golden-brown hue and striking dark and creamy stripes, mostly with a straight grain pattern.

Now, imagine taking all these beautiful wood varieties and going for an end-grain cutting board. When you cut on the end grain, that’s where the real magic happens. The wood grain on this surface creates a mesmerizing range of colors and contrasts. But here’s the best part: By skillfully arranging different types of wood, you can craft impressive and one-of-a-kind patterns, turning each board into a work of art. With the option of using various wood types simultaneously, the visual possibilities are truly limitless. Your creativity knows no bounds.

Cleanliness & Maintenance

When it comes to cleanliness and maintenance of wooden cutting boards, it’s a bit more involved than simply tossing a plastic board into the dishwasher. To ensure that your best cutting board remains hygienic and durable in the kitchen, it requires regular care and occasional refurbishment, such as sanding and reapplying oils or waxes. But if you’ve crafted your cutting board yourself, this should be no problem for you at all.

Wood has a natural advantage when it comes to cleanliness because it possesses natural antibacterial properties that can limit the growth of bacteria. As far back as 1994, the Food Safety Laboratory at the University of Wisconsin discovered that wood actually kills bacteria and labeled it as one of the most hygienic materials available. The reason behind this lies in wood’s natural components, particularly the polyphenols, as well as its ability to draw in moisture, thereby depriving bacteria of the moisture they need to survive.

In general, hardwoods are more resistant to contamination, especially by liquids, due to their tight grain structure and low porosity. Regular maintenance and handling of the cutting board are, of course, easier with smaller boards. However, one thing should be clear: Wooden cutting boards don’t belong in the dishwasher!

Application of wax every 4 weeks

Sanding and new surface treatment every 6 months

Daily care after use is straightforward: Use mild dish soap and a soft sponge to clean the board. Then rinse it thoroughly with clear water and wipe it dry.

Regularly applying special wax protects the board and preserves its beauty. But how exactly this is done and which oils and waxes are best and I use can be found in another article.

Sustainability

Choosing sustainable materials is an environmentally conscious decision that certainly aligns with your values. Count me in! And you know what? It’s not as complicated as it might initially seem. First and foremost, the industry provides various certifications and seals as useful tools to help us identify sustainable wood products and encourage responsible practices in the wood industry. These certifications are based on independent assessments and standards that take into account the environmental and social aspects of forestry. With your knowledge of these certifications and seals, you can make a significant contribution to your next wood purchase from the retailer. Just ask for these certifications:

Another option is to source sawn and dried wood from your local area. Simply browse through exchange platforms and forums or ask around. There’s always someone who knows someone. Especially in rural areas, there are plenty of opportunities to obtain suitable wood. However, don’t underestimate the additional effort, especially if you’re new to this. You often find larger wooden boards that may need additional drying and processing (removing sapwood and heartwood, cutting). This requires tools and knowledge.

You can also consider acquiring used furniture inexpensively or for free and reusing the wood. Here, you have the advantage that the wood moisture content should be suitable and the wood should be of good quality, provided it’s high-quality furniture. Especially older models are often crafted from solid wood in traditional craftsmanship. Fantastic!

Conclusion

What is a good cutting board? Absolutely, a wooden cutting board is the way to go. We’ve learned that wood can handle heat well and it provides long-lasting joy in the kitchen with regular care. When selecting the right wood, we prioritize high-quality, defect-free hardwoods with a moisture content of around 10-12%. The cutting board thickness and size depend on how you plan to use the board. Wood naturally has antibacterial properties, but it still needs regular cleaning and maintenance. The harder the material, the more resistant the cutting board is to wear and tear, odors and liquid penetration. By choosing different wood types, you can create beautiful designs, especially with end-grain boards. If you keep an eye out for quality certifications when buying wood or even better, repurpose wood, you’re contributing to sustainability. I hope I’ve been able to provide you with some essential pointers to assist you in your decisions. Whether you’re buying a wooden cutting board or designing and building one yourself, the goal is for it to be the best cutting board. In the upcoming articles, our journey will continue and you’ll learn more important details about how to make a cutting board. The next article will delve into choosing the right wood species for the best cutting board.