Why is the surface treatment of wooden chopping boards important?

Hygiene, durability & aesthetics

In my previous article I have already explained why the appropriate surface treatment of a wooden board is of crucial importance. Wood, as a product of nature, actively interacts with its environment. Fluctuations in humidity can cause the wood to swell or shrink, which in turn creates tension in the material and can lead to cracks.

Such cracks not only provide a breeding ground for bacteria, but also detract from the aesthetics of the cutting board. In the course of regular cleaning processes, wood tends to dry out due to frequent washing – a completely natural process. Indicators of this are the loss of surface gloss and an increasingly dry and rough feel.

Wooden chopping boards are subject to very high demands, especially when it comes to cuts, moisture, odors and cleaning. Adequate surface treatment with suitable oil or wax, or a combination of both, is essential. This treatment not only provides protection down to the top tenth of a millimeter (about 1-3mm for end grain), but also seals cracks, makes the surface easier to clean and helps to make the cutting board less susceptible to cracking.

The result is not only functional, but also gives the cutting board an aesthetic appearance.

Options for wood surface treatment

The range of methods for treating wooden surfaces is extremely diverse and varies depending on the stress and intended use. It ranges from oiling and waxing to glazing, staining and varnishing through to finishing with epoxy resins.

In this context, I will limit myself to the most common and at the same time most sensible method of surface treatment for chopping boards – the application of wood oil and wax.

Oils

Oils are a broad category of organic liquids that cannot be mixed with water. This group includes vegetable oils such as olive oil, animal oils such as cod liver oil, mineral oils obtained from crude oil or coal, and purely synthetically produced silicone oils that have no organic components.

As part of my further consideration in the context of wooden cutting boards, I will focus on the group of vegetable oils. These are obtained by mechanically pressing and extracting oil-containing seeds and fruits. Compared to water, vegetable oils have a higher viscosity.

Subdivision of the oils

Drying and non-drying oils

Some of you have probably heard phrases like:“I oil my chopping board with olive oil, the natural way!” or perhaps with rapeseed oil or walnut oil. While these are common practices, it is crucial to understand the chemical processes involved with these different oils.

These processes significantly influence whether an oil should be applied frequently or only after prolonged use, and also have an effect on the cleaning of the board. Oil that does not dry is washed out again within a short time. This leads us to a crucial subdivision that is decisive in determining whether a particular oil is useful for the surface treatment of wooden boards or not.

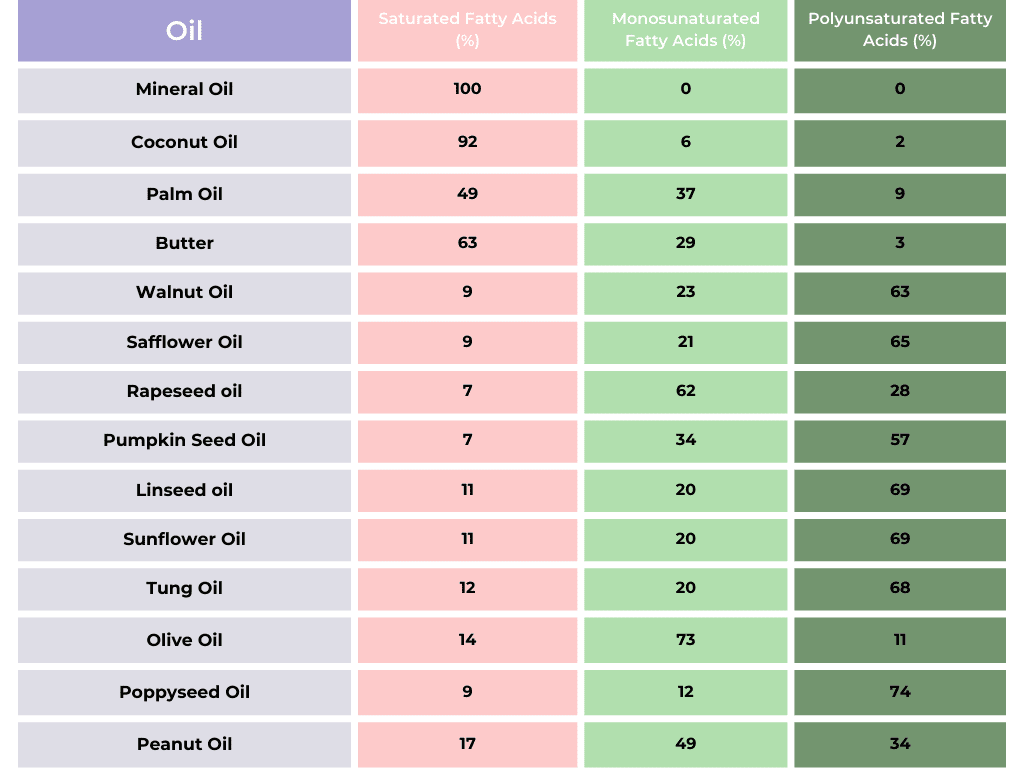

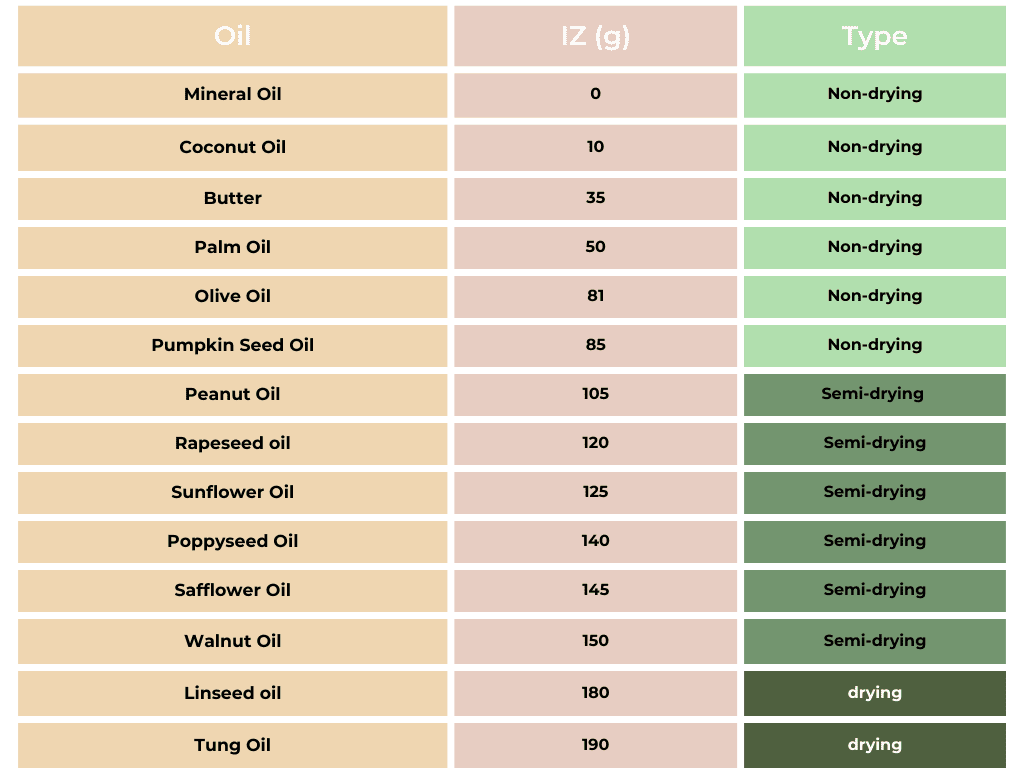

A distinction is made between drying, semi-drying and non-drying oils. Whether an oil dries or not depends on the content of polyunsaturated fatty acids.

Oils are able to dry under the influence of atmospheric oxygen (oxidation) in that the dissolved polyunsaturated fatty acids (omega-3 fatty acids e.g. linolenic acids or omega-6 fatty acids e.g. linoleic acid) absorb oxygen and thus cross-link to form more complex molecules (peroxides) and form a viscous, resinous mass (polymerization = cross-linking). Some oils (linseed oil) require light to dry completely.

The iodine number (g) is used for classification. The iodine value (also iodine value) is a measure of the unsaturated compound content of a fat. The higher the proportion of unsaturated fatty acids, the higher the iodine value and the more likely oils are to thicken (polymerize) and thus dry out.

A natural oil can only dry completely if it contains sufficient polyunsaturated fatty acids, e.g. linseed oil or tung oil. Note that drying pure oils can take several weeks.

Classified in:

- Non-drying oils with an iodine value < 100,

- Semi-drying oils with an iodine value of 100 – 150 and

- Drying oils with an iodine value > 150

It is important to emphasize that the iodine number says nothing about the duration of the drying time. In contrast to drying oils, semi-drying and non-drying oils never harden completely.

They are therefore only suitable for use on wooden cutting boards to a limited extent or not at all. They only offer limited surface protection and are quickly washed out again. When using them, it is therefore necessary to re-oil the cutting board regularly (sometimes after every wash of the board). Another disadvantage is that the oil becomes rancid, which can result in an unpleasant odor and also creates a suitable environment for bacteria.

When using non-drying or semi-drying oils for surface care, regular application at short intervals is necessary as the oils are quickly washed out and lose their effect.

Hard oil

Hard oils belong to a category of oils that harden particularly robustly. Typically, hard oils are used as a water-repellent yet breathable base treatment for wood surfaces subject to heavy wear. They can also be used as a finishing treatment for less stressed surfaces.

The name “hard oil” refers less to the ingredients of the oil than to its properties and application.

The composition includes oil mixtures such as tung oil, linseed oil and nut oil as well as dissolved synthetic and natural resins such as pine resin and hardwood resin. Hard oils are available in both solvent-based and solvent-free form. Solvent-free hard oils are also available with the addition “Pure Solid“, i.e. 100% solids content.

They also contain drying agents (siccatives) that shorten the drying process on the surface of the wood from days to a few hours. Nevertheless, the complete deep drying of the oil takes several days, as can be seen from the processing instructions for the individual products.

Depending on the solvent content or degree of dilution, hard oils penetrate deep into the wood and, unlike hard wax oils, leave either no or only a very thin surface film.

Surfaces treated with hard oil and completely dried are characterized by high mechanical resistance and water repellency, but require regular refreshing.

FORMS A PROTECTIVE COAT: The oil penetrates deep into the raw wood surface and provides resistant and water-repellent protection. Also resistant to many household chemicals

IDEAL WOOD CARE: This special care oil for heavily used solid wood makes the surfaces durable, tread-resistant and resistant to water stains. The wood is impregnated

SIMPLE APPLICATION: Apply to the cleaned surface to be treated with a brush or oil roller. Allow to soak in for 20-30 minutes. Remove excess oil completely with a cloth

MANY AREAS OF APPLICATION: This wood hard oil is suitable for the basic treatment and renovation of many types of wood indoors and weather-protected surfaces outdoors, e.g. floors, stairs, doors, wall cladding

Hard wax oil/hard oil wax

Hard oil waxes are a sophisticated mixture of hard oil and a wax content of around 5%. This special category of oil/wax mixtures combines the beneficial properties of oils and waxes and makes them particularly suitable for wood surfaces subject to heavy wear, such as floors or worktops.

The oil it contains penetrates deep into the wood fibers, while the wax forms a protective film on the surface. This dual function not only makes the treated wood surfaces resistant to heavy loads, but also preserves their breathability, open porosity and water repellency.

The solid content in hard oil waxes varies depending on the manufacturer and ranges from 50% “High Solid” to solvent-free “Pure Solid” variants.

For some manufacturers, all ingredients, including oils, resins, solvents and waxes, are of natural origin, of natural origin . This includes the use of natural resins, solvents such as balsamic turpentine or orange oil and waxes such as carnauba wax or beeswax.

Depending on the application, synthetic ingredients can improve and optimize the properties of the hard wax oil. These include waxes made from kerosenes, modified vegetable oils and synthetic drying agents, which considerably shorten drying times. This is particularly important for applications such as floors that need to be walked on quickly.

Other suppliers rely on two-component variants in which oiling and waxing are carried out in two different work steps with corresponding intermediate drying.

The hard wax oil is a solvent-free special oil. It is easy to apply, easy to repair and has a silky matt finish.

Diffusible and antistatic

Tread-resistant, dirt and water-repellent and antistatic

Resistant to saliva and perspiration

High Solid vs. Pure Solid

For the surface treatment of wood, it is important to understand the significance of the solids content in oil mixtures . These mixtures are made up of solids such as oils, resins, pigments and drying agents, and waxes can also be added depending on the formulation. These solids remain in the wood after the solvents and/or water components have evaporated.

The solids content in the oil mixture can cover a range from 20 to 100%. The selection of the appropriate solids content depends on the type of wood and the intended surface application. The fiber saturation and penetration depth of the wood play a decisive role here.

Dense and hard wood usually requires a lower solid content to ensure that the oil can penetrate effectively. These distinctions help to select the optimum oil mixture for specific types of wood and applications.

Manufacturers often use terms such as “high solid” or “pure solid” for classification purposes. Products with the “High Solid” label generally have a solids content of around 50-60% (depending on the manufacturer), while “Pure Solid” products are solvent-free, water-free and therefore offer a 100% solids content.

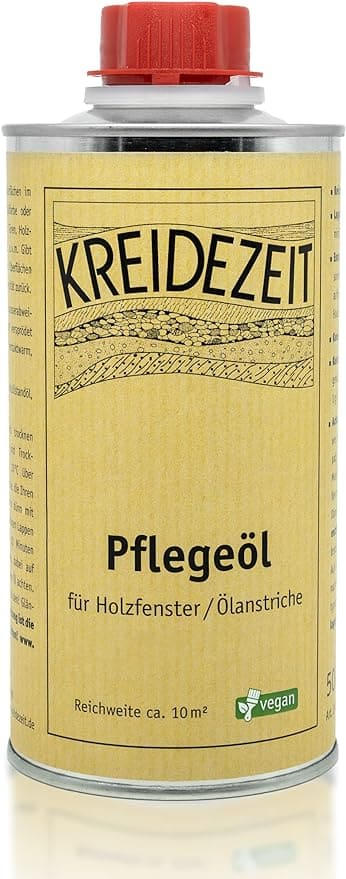

Maintenance oil

Maintenance oils represent a special category within the oil mixtures and are characterized by a lower solids content, which is usually between 15 and 30%. The name “maintenance oils” already indicates that these oils are designed for refreshing wood surfaces that have already been oiled.

The reduced solids content makes it easy to apply, especially on already treated surfaces, to give them a new shine. Maintenance oils not only freshen up the appearance, but also help to maintain the protective layer that protects the wooden board from moisture, wear and other influences.

Kreidezeit Maintenance Oil restores protection and original color intensity to weathered, dull and pale surfaces.

Kreidezeit care oil contains neither solvents nor water and consists exclusively of natural oils. It contains no “hidden” alkyd resins, e.g. made from non-drying oils such as rapeseed, soybean or sunflower oil.

Kreidezeit Maintenance Oil is used to maintain exterior surfaces that have been painted with Kreidezeit Stand Oil Paint or colored wood stain: Windows, doors, wooden façades, timber framing, play equipment, carports, etc. Resistant to scratching, dirt and water-repellent and antistatic

Keep work materials soaked with product, such as cleaning cloths, sponges, sanding dusts, polishing pads with oil that has not dried through, in an airtight metal container or in water, and ensure that no oil comes into contact with porous insulating materials when spreading, as otherwise there is a risk of spontaneous combustion due to the vegetable oil content. The product itself is not self-igniting. Do not pour product onto surfaces. Store out of reach of children. Pay attention to possible allergies to natural substances.

Mineral oil

Mineral oils are complex mixtures produced by the distillation of mineral raw materials such as lignite, hard coal, peat, wood and crude oil. These oils consist mainly of saturated hydrocarbons of various forms and alkenes. Originally obtained as by-products, mineral oils are used as lubricants, solvents or stains.

In the medical world, they are also known as medicinal white oil, which meets the highest standards of purity and compatibility. It is colorless, odorless and tasteless and free of aromatics and sulfur compounds.

Mineral oils are non-drying oils, which means that they do not solidify through oxidation. This makes them less suitable for the surface treatment of heavily used wooden surfaces, unless they are regularly re-oiled at short intervals.

As mineral oil does not dry, it can spread well in the wood and ensure an even appearance. The ability to re-oil it without further pre-treatment makes it a practical option for maintenance measures. Mineral oils are mainly used as polishing oils.

Howard Cutting Board Oil is made from clear, odorless, food grade mineral oil. The penetrating effect of this food-grade mineral oil emphasizes the depth of the grain in the wood and prevents drying out and cracking. Howard Chopping Board Oil is perfect for the initial “oiling” of chopping boards and butcher blocks. The mineral oil that can be used as cutting board oil comes from untreated mineral oils and has had no contact with nuts or gluten during production, storage or transportation.

Common oils

Linseed oil (IZ180)

Linseed oil is obtained by extraction with a solvent or by cold and hot pressing the oily brown or yellow seeds of the linseed plant (flax). It burns strongly, yellows on softwood, is self-igniting and self-drying.

Crude oil

Cold presses are used to extract linseed oil for pharmaceutical purposes and for linseed oils for consumption. This type of pressing is particularly gentle. In the field of linseed oil extraction for technical applications, the seeds are industrially cold-pressed as well as hot-pressed. To prevent oxidation during pressing, this takes place under a protective atmosphere (without oxygen).

Raw linseed oil is rich in ingredients and has different colors depending on how it is pressed and the type of plant. Cold-pressed linseed oil is golden yellow, hot-pressed oil is more yellowish-brown. The cloudy appearance is due to the suspended plant matter it still contains. mucilage.

The residue from the pressing process is also called linseed press cake, which is rich in animal proteins and is used as animal feed. 1kg of crude linseed oil is obtained from 4kg of linseed.

Raw linseed oil

The crude oil is only cleaned after filtration to remove suspended solids. The mucilage is then removed and bottled as quickly as possible in an airtight container to prevent oxidation. If oxygen reaches the oil, the unsaturated fatty acids oxidize and the oil becomes rancid.

Raw linseed oil is thin and can therefore be used as a nutritional oil (virgin oil). As raw linseed oil hardens only slowly, it is already suitable for technical use as a wood preservative.

Cold-bleached linseed oil is produced when raw linseed oil is pre-oxidized with the addition of oxygen and thus hardens more quickly during subsequent processing. This variant is free of chemical additives and has a slightly lighter color compared to pure crude oil.

Half oil

Half oils consist of half linseed oil (also linseed oil varnish) and half solvent (e.g. balsamic turpentine oil). They are very thin and penetrate deep into the wood, but offer only reduced wood protection and serve more as a primer for untreated wood surfaces.

Boiled linseed oil

The purified raw linseed oil is boiled at temperatures above 100°C. The oxidation process is set in motion and the oil is thus pre-oxidized. Boiled linseed oil is somewhat more viscous and does not penetrate the wood as well as raw linseed oil. However, it can be applied in thicker coats as an opaque coating and offers good weather protection.

Linseed oil varnish

While raw linseed oil takes several weeks to dry, the use of linseed oil varnish shortens the drying time. Linseed oil varnish is produced by adding siccatives and other substances to linseed oil, followed by a boiling process. These additives change the consistency of the oil and accelerate the drying process, during which the product hardens by absorbing oxygen from the air.

At the same time, a protective, water and dirt-repellent film forms on the wood, similar to varnish. In contrast to varnish, however, linseed oil varnish penetrates the wood pores, protecting the wood not only from the outside but also from the inside. The wood can still absorb and release moisture, in contrast to a lacquer finish.

The main raw material for oily natural paints is linseed oil, which is obtained from the flax or linseed plant. Wood treated with pure linseed oil is only completely dry after several days. To improve the poor drying properties, drying agents are added to linseed oil. By definition, linseed oil is then called linseed oil varnish.

Linseed oil varnish offers solvent-free surface protection for all interior wood that is subject to little wear and tear, especially furniture, doors, worktops, wall paneling, beams, etc. It accentuates the wood grain in a warm tone, is very economical and can be reworked locally if damaged. In addition, it is free of cobalt, lead and barium, and is weld- and saliva-resistant in accordance with DIN53160.

Stand oil

Stand oil, also known as linseed oil, is a special variant of linseed oil that is produced through a targeted oxidation process. In the conventional method, raw linseed oil was exposed to the sun for several months, allowing the oxidation process to develop naturally. The resulting oil was polymerized and viscous.

In modern production processes, raw clarified linseed oil is boiled at high temperatures of around 300°C or aerated by blowing in oxygen (constant circulation process). This process makes the stand oil more viscous and lighter in color. By adding drying agents, known as siccatives, the drying time is shortened and curing takes place without volume change, minimizing the risk of cracking.

Stand oil is often used in the production of stand oil paints, which are often mixed with solvents such as balsamic turpentine for better processing. These paints are known for their deep penetration into the wood and the formation of a hard-wearing surface. Regular maintenance in the form of re-oiling or repainting is nevertheless essential.

Silky wood coating made from linseed oil and mineral pigments with good coverage and high elasticity. Also suitable for ferrous metals. Looks like a matt lacquer. With regular care, the even weathering results in easily renovated coatings that will last for years. Completely resin-free, therefore suitable for use in listed buildings.

In three colors: 146-16 pine, 146-74 grey and 146-90 white.

Consistently ecological selection of raw materials. Easy to apply, easy to renovate. Resin-free; does not peel, crack or burst (high elasticity). Opaque, glossy, weather-resistant. Open to diffusion and free from wood preservatives.

Lacquer linseed oil

Lacquer linseed oil undergoes a special cleaning process in which it is deacidified, degummed and bleached. The result is a high-quality, intensively purified, bleached linseed oil that is free from mucilage and other impurities in its pure state. Varnish linseed oil is used as a raw material for paints and varnishes, and after a further heating process it is processed into stand oil.

Tung oil, also wood oil (IZ190)

Tung oil, a natural product, is obtained from the seeds of the Chinese tung tree (Aleurites fordii). This tree, mainly found in China, produces flowers from which ripe seeds are extracted. The oil obtained, pure tung oil, is used as a base for wood oil, paint or ink.

Tung oil is characterized by its viscous consistency and distinctive, nutty smell. Mechanically resistant and water-resistant, it offers twice the protection factor of linseed oil. It emphasizes the grain, hardly darkens at all and is food-safe when dry without any chemical additives.

In its liquid state and during processing, tung oil can cause allergic skin reactions and requires the wearing of gloves and a filter mask!

Tung oil is particularly suitable for interior areas subject to heavy use, such as furniture and floors. It can also be used outdoors to a limited extent, but it lacks UV protection, which means that wooden surfaces can quickly turn gray. Due to its distinctive odor, the use of pure tung oil is not recommended for interior furniture parts such as drawers or cabinet interiors.

The oil extracted from the fruit of the tung tree can be used in a variety of indoor and outdoor applications, e.g. for furniture, garden furniture, floors, turned parts, musical instruments, wooden toys and wooden boats as well as an impregnation for fabrics and even masonry. Tung oil is absorbed deep into the wood surface, which hardens it after drying, making it mechanically more resistant and highly water-resistant (about twice the protection factor compared to linseed oil). It deepens the colors and increases the contrast of the grain. Nevertheless, the wood retains its natural look and feel, the protective film is also elastic in the long term and, unlike linseed oil, hardly darkens at all. Refreshing or repairing is possible by applying a new bale. Lignea can be applied easily, even in several coats, with a bale or brush. It can be diluted with turpentine or mixed with other vegetable oils (e.g. linseed oil, camellia oil) according to your own recipe.

Poppy seed oil (IZ140)

Poppy seed oil, obtained from the seeds of the white-flowered poppy (Papaver somniferum), has a long tradition and used to be the most important binding agent for high-quality artists’ varnishes and oil paints. It has a light, almost transparent color, does not yellow, is almost odorless, darkens slightly and is food-safe in its pure state.

Poppy seed oil is semi-drying (dries more slowly than linseed oil) and therefore has a lower final hardness. It is therefore used as surface protection in interior areas subject to light wear. It regulates moisture, is open-pored and permeable to diffusion. Poppy seed oil is also suitable as a base for color oils and artists’ paints.

Food-safe oil from the seeds of the white-flowered poppy (Papaver somniferum), ideal for handicraft objects, turned parts, toys, kitchen furniture and kitchen utensils, also for knife and tool handles due to its grip and, together with pigments, for the production of high-quality color oils and artists’ paints. Due to its high transparency, poppy seed oil forms the base material for violin varnishes and other clear wood protection coatings; it offers good protection against moisture and dirt, does not yellow and strengthens the wood surface due to its deep penetration. Poppy seed oil dries more slowly than linseed oil. Repeated application results in a warm, silky sheen and a pleasant surface feel. Poppy seed oil can be mixed with any other vegetable oils and thinners.

Walnut oil (IZ150)

Walnut oil is a high-quality and expensive vegetable oil that is obtained from ripe, sometimes roasted walnut seeds. It has a pale greenish-yellow to straw-yellow color, is relatively thin and has an intense, nutty taste. It is characterized by a particularly high content of unsaturated fatty acids and has a limited shelf life even when refrigerated.

The highest quality walnut oil is obtained by cold pressing (native and not long-lasting) and subsequent filtration, while hot pressing leaves it neutral in taste and odor but with a relatively long shelf life. It is food-safe in its pure form and is used for technical painting purposes and as surface protection for low stress.

Walnut oil is a semi-drying oil and can be used as an alternative to linseed oil if you want to avoid the smell of linseed oil, but it dries out more slowly and not completely. As a wood preservative, it requires regular refreshing as it washes out.

Pressed from 100% Californian walnuts, this food-safe oil is the only nut oil that is suitable for painting and surface protection. Other types of nuts produce non-drying oils. In terms of both its chemical structure and its properties, walnut kernel oil is somewhere between linseed oil and poppy seed oil, although it is somewhat closer to poppy seed oil. This also applies to its delicate coloring. The significantly shorter drying time compared to poppy seed oil and the remarkably low tendency to yellowing, in addition to its thinness and high pigment absorption capacity, are most likely the reasons why this oil is not only praised in old Italian painting books, but was also very popular with the Dutch and Germans according to tradition. Ideal for handicraft objects, turned parts, toys, kitchen furniture and kitchen utensils, also for knife and tool handles due to its grip and, together with pigments, for the production of high-quality colored oils and artists’ paints.

Perilla oil (IZ170)

Perilla oil, also known as egoma oil, is obtained from the roasted clauses (seeds) of the green-leaved variety of the perilla plant (Perilla frutescens). The plant is native to East and Southeast Asia and originally comes from the mountainous regions of India and China. The light, yellow oil is reminiscent of linseed oil in taste and smell. It is also grown in countries such as Austria and the USA.

Perilla oil is rich in omega-3 fatty acids and is mainly used in salads and cold dishes due to its nutty flavor. It is also used in medicine and cosmetics due to its anti-inflammatory and skin-caring properties. It is a drying oil and is therefore also suitable for the production of paints and inks, as well as for the care of wooden surfaces.

Camellia oil (IZ80)

Camellia oil, also known as egoma oil, is obtained from the seeds of the Chinese camellia tree by gentle cold pressing. It is a purely natural product with no chemical additives and has a clear to slightly yellowish color. The oil is relatively low-viscosity, low-odor, food-safe and non-drying.

It brings out the natural beauty of the wood grain, but does not harden in its pure form and therefore offers only limited protection against moisture and dirt. It is well suited for diluting viscous wood oils, such as tung oil, to improve the application and penetration behavior. Camellia oil is also used for polishing shellac polishes and as an anti-corrosion agent for steel tools, as it is acid-free and non-resinous.

Versatile, low-viscosity oil from the seeds of the camellia tree:

Corrosion protection: The acid-free, non-resinous and non-volatile oil is the ideal rust inhibitor for tools, knife blades and weapons. Purely vegetable and food-safe, it is ideal for preserving kitchen knives made of carbon steel.

Wood protection: The low-viscosity oil is quickly absorbed into wood and protects against moisture, dirt and UV radiation. Clear and non-discoloring, it brings out the grain. It does not harden.

Body care: Camellia oil forms the basis of many ointments, creams and soaps. As a massage and hair oil, it has always been irreplaceable for Japanese geishas.

Safflower oil (IZ145)

Safflower oil, also known as safflower oil, is a vegetable oil obtained from the achenes (fruits) of safflower. It becomes an edible oil through cold pressing and a technically usable oil through hot pressing. Safflower oil is a slow-hardening oil whose final strength is reached after about 4 weeks.

After boiling for twelve hours, a gelatinous mass called Afridi wax is produced, which is used as a substitute for linseed oil in the production of linoleum. The oil hardly yellows at all and is used to produce varnish, varnish and oil paint. Safflower oil can be added to casein paints to improve workability and adhesion.

Improves adhesion and reduces stress

Particularly low yellowing

Free from additives

Safflower oil is a natural drying oil obtained from the seeds of safflower. Among the drying oils, safflower oil is a particularly low-yellowing oil. It is therefore used in low-yellowing paints and varnishes. Recommended as an adhesion-improving and tension-reducing additive to casein marble powder paint for painting over emulsion paints. To do this, add 3 – 5 %, i.e. 30 – 50 ml of safflower oil per kg of color powder to the ready-mixed casein color. For low-yellowing wood surface treatments indoors. Not suitable for floors.

Orange oil

Orange oil is obtained by cold-pressing the fruit peel of the sweet orange (Citrus sinensis) or bitter orange and is a so-called essential, rapidly volatile and drying oil. It is a purely natural product with no chemical additives. The oil has an intense orange scent, is highly grease-dissolving and evaporates without leaving any residue when it dries. It also has an orange color.

In its pure form, the oil is mainly used as a cleaning agent for wood and glass surfaces. Due to its pleasant fragrance, it is added to oils and waxes in small quantities as a diluent. It is also used as an additive in fragrance oils, creams and soaps.

However, it should be noted that discoloration is possible on very light-colored surfaces and untreated wood surfaces. Due to the high content of citrus acids, orange oil in its pure form can cause irritation to the skin and mucous membranes. Orange oil should be stored away from light. It has a limited shelf life in contact with oxygen.

Low-viscosity oil from the peel of the sweet orange, ideal for diluting vegetable wood preservative oils and – thanks to its strong grease-dissolving power – also as a household cleaning agent. Adding 1-5 % to linseed oil or tung oil significantly improves the penetration properties, makes application easier and gives these oils a vitalizing fragrance. In combination with beeswax or carnauba wax, balms can be produced for the care and cleaning of wooden surfaces, antiques or leather. This oil is also ideal as a fragrance oil.

Free from additivesFlammable liquid and vapor. May be fatal if swallowed and enters the respiratory tract. Causes skin irritation. May cause allergic skin reactions. Toxic to aquatic organisms, with long lasting effects.

Balsam terpentine oil

Balsamic terpentine oil is obtained by double distillation from the resin of the maritime pine (Pinus pinaster) and is one of the highest quality solvents on a natural basis, which is highly valued in art painting and for handicraft applications. It should not be confused with the so-called “turpentine substitute”, a mineral oil product.

The oil has an intense smell of pine, is highly fat-dissolving, evaporates without residue when dry and is colorless. It is used as a thinner for vegetable oils, oil paints, oil varnishes, painting primers and for dissolving resins, waxes and for the production of varnishes and polishes. It is also used as a brush cleaner.

Large-scale indoor applications should only be carried out with good ventilation and sufficiently long drying times. Allergic reactions are possible on contact with mucous membranes.

One of the highest quality solvents on a natural basis, ideal for thinning vegetable oils, oil paints, oil varnishes and for the production of varnishes and polishes with resin, wax or pigment components. The low-viscosity oil, obtained by double distillation from the sap of the maritime pine, is colorless and has a fresh, ethereal scent.

Olive oil (IZ81)

Olive oil is a vegetable oil obtained from the pulp and kernel of olives, the fruit of the olive tree. It has been produced for at least 8000 years and has a density of 0.914 to 0.919 g/cm³. Unlike most other vegetable oils that are produced by refining, virgin olive oil is a purely natural product.

Olive oil is made up of 77% monounsaturated, 9% polyunsaturated and 14% saturated fatty acids. The color of an olive oil can vary from green-brownish to light yellow, depending on the substances contained in the olives and the state of ripeness. The color has no influence on the quality of an oil. Olive oil is often used as a foodstuff, but it can also be used for wood care.

The low proportion of polyunsaturated fatty acids makes olive oil a non-drying oil, which must be reapplied regularly as a surface treatment, as it does not solidify and washes out easily.

Rapeseed oil (IZ120)

Rapeseed oil is a vegetable oil obtained from the seeds of rapeseed (Brassica napus) or, more rarely, from oilseed rape (Brassica rapa subsp. oleifera). The cultivation and production of rapeseed oil has multiplied and today it is mainly used as food, lubricant and biofuel.

Rapeseed oil contains various nutrients and plant substances, including resins, waxes, phospholipids, free fatty acids and more. Pure rapeseed oil is food-safe and is a semi-drying oil. When used as a surface protection for wooden surfaces, it should be noted that it never hardens completely and once it has penetrated the wood it is difficult to remove. It leaves an oily feel on the surface.

Sunflower oil (IZ125)

Sunflower oil is a vegetable oil obtained from the seeds of the sunflower. It has a light yellow color, is heat-resistant, food-safe in its pure form, has a mild taste and is rich in unsaturated fatty acids. Sunflower oil is mainly used for food, but it is also used to produce biodiesel and for pharmaceutical and technical purposes.

It is only semi-drying and can only be used to a limited extent for the treatment of wooden surfaces.

Coconut fat, also coconut oil (IZ10)

Coconut oil, also known as coconut oil or coconut fat, is a white to yellowish-white vegetable fat obtained from the nutritive tissue of the coconut. It has a very high proportion of saturated fatty acids and is mainly used in the kitchen for baking, frying and deep-frying. It is also used in the confectionery industry, for pharmaceutical and cosmetic purposes and as a starting material for oleochemistry.

Coconut oil smells mild and has a waxy consistency. It is also known as coconut oil as it is solid at room temperature. The oil consists mainly of saturated fatty acids and has only a small proportion of unsaturated fatty acids, making it a non-drying oil. This means that it cannot be used as permanent wood protection.

Medicated white oil (IZ0)

White oil, also known as kerosene oil, is a mineral oil and is a colorless, odorless and tasteless oil that is obtained from refined crude oil. It consists mainly of saturated aliphatic hydrocarbons. White oil is used in various industries such as pharmaceuticals, where it serves as a carrier in some medicines. In the food industry, it is used as a lubricant for machines and as an additive in certain foods. In the cosmetics industry, it is contained in skin care products, lip balms, ointments and creams.

White oil is also used in technical applications, for example as a lubricant, in the textile industry and in plastics processing. Due to its neutrality, it is well suited as a carrier in applications where a tasteless and odorless oil is required. White oil is a non-drying oil and does not harden, which is an advantage in some applications, but should not be used as permanent wood protection for surface treatment.

Wax

The definition of waxes is based on their mechanical and physical properties, although their chemical composition and origin can vary greatly. A substance is considered a wax if it is kneadable at 20 °C and has a consistency ranging from firm to brittle hard.

The structure varies from coarse to fine crystalline, the transparency from translucent to opaque, and the color ranges from transparent to yellowish-brownish. Waxes are light-resistant, not glassy and only melt above 40 °C without decomposing.

They become slightly liquid just above the melting point and their consistency and solubility depend on the temperature. Their resistance increases as the melting point rises. Waxes can be polished under light pressure, and solvents need to be added for better processing of solid waxes.

Applied waxes can be removed from wooden surfaces by applying solvents (wax remover) or by mechanical means.

Waxes can be of natural origin or synthetically produced. They are available in pure form as well as in oil mixtures (hard wax oil), wax stain and shellac mixtures.

Subdivision of waxes

Natural waxes

Natural waxes belong to the lipid family and are complex mixtures of substances that can be divided into fossil and recent (non-fossil) waxes. The main components of these natural substance mixtures are esters of fatty acids, also known as wax acids, with long-chain, aliphatic, primary alcohols, the so-called fatty alcohols. In contrast to fats and fatty oils, which are triglycerides with fatty acids, natural waxes also contain free, long-chain aliphatic carboxylic acids, ketones, alcohols and hydrocarbons.

Natural waxes are usually obtained by extraction and subsequent cleaning and bleaching. Natural waxes can also be refined or chemically modified for special applications. Vegetable waxes and beeswax have been in use for thousands of years.

The waxed surface remains breathable and at the same time seals the wood against the influence of fluctuating humidity. At the same time, wax offers good water protection, is easy to repair, as minor damage or wear and tear can be easily repaired with a new coat of wax, and the waxed surface feels pleasant and very natural to the touch.

Animal waxes

Animal waxes, such as wool wax, China wax and beeswax, are natural waxes. Other representatives of animal waxes are tallow, insect waxes and lanolin (wool wax). Mycobacteria, a group of bacteria, form an outer shell of special waxes called phthiocerols.

These waxes, produced by animals, consist mainly of esters of fatty alcohols and carboxylic acids such as palmitic acid. The areas of application for these animal waxes range from cosmetics and pharmaceuticals to the food industry.

Vegetable waxes

Vegetable waxes are natural waxes produced by plants. They are obtained from various vegetable oils such as soybean oil, rapeseed oil, castor oil, sugar cane wax, carnauba wax and candellila wax. These waxes have a wide range of applications in areas such as cosmetics, pharmaceuticals, the food industry and in the household.

Mineral waxes

Mineral waxes, also known as petroleum waxes, are composed of various sources and consist mainly of hydrocarbons. These include petroleum wax (mineral oil wax), geological earth waxes such as ozokerite and the ceresin produced from it, recent sediments of crude petroleum, including wax-rich (stuff wax, vein wax) and wax-poor (lep wax) material, as well as fossil plant waxes such as peat wax and montan wax, a lignite derivative.

Among the petroleum waxes, macrocrystalline kerosene waxes (kerosene) and microcrystalline waxes (microcrystalline kerosene wax) are of particular interest. These are mainly used in the candle industry, while kerosene emulsions made from kerosenes are used in the paper, corrugated board and packaging industries.

Hard kerosene from crude oil dominates over 90% of global production, while hard kerosene from lignite extraction is important for certain countries.

Synthetic waxes

Synthetic waxes are the result of chemical synthesis processes in which products such as crude oil or lignite are used as starting materials. These waxes, such as polyethylene wax, propylene wax and Fischer-Tropsch waxes, are used in various industries, including cosmetics, pharmaceuticals, food, paper and textiles.

Semi-synthetic waxes are created from natural waxes, whereby montan wax often serves as the basis, and are subject to physical or chemical changes.

The variety of synthetic waxes includes ester waxes, amide waxes, Fischer-Tropsch waxes and polyester waxes.

Common waxes

There are many different waxes on the market that are suitable for all kinds of applications. However, I am concentrating on the waxes that are particularly interesting for the treatment of wooden surfaces.

Beeswax

Beeswax, also known as “cera” or “yellow wax”, is a substance produced by honey bees for the construction of their honeycombs. Natural beeswax is soft, pleasant smelling and yellowish in color. The yellow color is caused by carotene absorbed from the pollen, while freshly exuded wax flakes are white.

This wax is soluble in turpentine oil or heated alcohol and liquefies at temperatures above 60°C. It has moderate resistance to water and mechanical stress and is easy to polish.

For the treatment of stressed wooden surfaces, it is recommended to prime with oil before applying beeswax.

Purified and bleached white beeswax is commercially available under the name “Cera alba”. Synthetically produced beeswax does not achieve the same properties as its natural counterpart.

Although beeswax has been replaced by artificial wax in some areas of application, it is still used in the cosmetics and pharmaceutical industries. In technical applications, it is processed into wax varnish, emulsion, paste paints and oil-based paints.

Premium wood wax made only from BIO certified oilseeds with pure BIO beeswax. Colorless, absolutely odorless, without chemicals and without solvents. Suitable for allergy sufferers.

Furniture care: suitable for all real wood furniture (including antique furniture). As it contains no chemicals, the surface is not attacked. Gloves not necessary as natural product.

Woodworkers: rub a thin layer of wood wax onto the already oiled surface and leave to soak in overnight. Then polish up. Gives a velvety matt shine. Works ON the wood!

Application: Surface must be dust-free. Apply wood wax very sparingly and rub in in the direction of the grain. Remove excess wax the next day with kitchen paper and polish.

Carnauba wax

Carnauba wax, also known as “Brazilian wax”, is obtained from the leaves of the Brazilian carnauba palm. The natural color palette of the raw wax ranges from dirty yellow to brown to green. The high-quality “Flower” wax is characterized by a yolk-yellow color and is free from impurities.

As the hardest natural wax, carnauba wax is mainly used in release agents and polishes. It is obtained by tapping and scraping the powdery wax layer from the leaves of the carnauba palm. With a high melting temperature of 80 to 87°C, it is insoluble in water but soluble in various organic solvents. The main producer of carnauba wax is Brazil, where most of it is processed into powder.

Carnauba wax is used in a variety of industries. In the food and cosmetics industries as well as in the medical and paint industries, it acts as a release and coating agent, preserves citrus fruits and is used as an ingredient in care products for furniture, car polishes and cosmetic products. It improves the scratch resistance of surfaces, particularly in the coatings industry.

Carnauba wax is commercially available both in flake form and as an emulsion concentrate. It is ideal for the treatment of wooden surfaces in the form of a wax mixture, as it is food-safe, free from allergenic fragrances, resistant to water and mechanical stress and easy to polish.

Carnauba wax emulsion concentrate is obtained from the leaves of a Brazilian palm species. In the rainy season, the thin wax film has a water-repellent effect. In summer, this thin layer of wax has a protective effect against drying out. Tested in the harsh climate, this material is also excellently suited for use as an emulsion. A diffusion-open treatment is important so that the natural properties of a wooden floor can be retained. The carnauba wax emulsion gives floors additional protection against mechanical abrasion as well as dirt and water.

Carnauba wax emulsion is suitable for oiled, waxed wood and cork floors as well as tiled floors and furniture. Also for the sole treatment of untreated interior sides of wooden cabinets and for untreated wooden beams and paneling . Suitable as an additive to mop water for the care of waxed or oiled floors. On very smooth floors, use the emulsion sparingly due to the risk of slipping.

The emulsion is a very rich concentrate for dilution with water and is therefore extremely economical. Canauba Wax Emulsion Concentrate is self-polishing and does not need to be polished. If necessary, a gloss increase can be achieved by polishing.

Carnauba wax is used as a raw material for e.g. waxes, oil waxes and emulsions. Vegan. Carnauba wax (in dandruff) is vegan!

Candelilla wax

Candelilla wax, also known as candellina wax, is a hard, brittle wax obtained from the leaves and stems of the candelilla bush in northern Mexico and the southwestern United States. With a melting point of 67 to 79°C, it has a yellowish to brownish color. The main components of wax are hydrocarbons.

It is produced by boiling the leaves with diluted sulphuric acid, skimming the wax from the surface and then cleaning it in several steps. Candelilla wax in its pure form is considered harmless to health.

It is used in the cosmetics, pharmaceutical and food industries. It is also used in wood care, where it forms a protective layer on the wood surface and protects the wood from moisture and dirt.

When using care and cleaning products, it should be noted that candelilla wax is not suitable for all purposes due to its hardness. It is recommended to apply the wax thinly and work it well into the wood. Despite its hardness, candelilla wax remains pleasant to use, even at higher temperatures.

Candelilla wax is currently subject to EU import regulations.

VEGAN WAX ALTERNATIVE – our candelilla wax (EUPHORBIA CERIFERA CERA) is a pure vegetable wax from the Mexican candelilla bush and is also suitable as a vegan alternative to beeswax due to its melting properties

IDEAL CONSISTENCY PROVIDER – Candelilla wax is harder than beeswax, but softer than carnauba wax. It gives creams and ointments the right consistency and provides natural cosmetic variety: homemade creams, ointments or lip balms

PURE PLANT-BASED – Candelilla wax is extracted from the candelilla bush, which is native to northern Mexico. It is a purely vegetable & natural wax, without additives, ODORLESS AND NEUTRAL – the vegetable wax is odorless

Natural oil-wax mixtures

You will find a variety of wax mixtures on the market, which may also contain natural oils (linseed oil, walnut oil) and/or solvents (balsamic turpentine). These are often combined with bee and carnauba waxes.

If a particularly natural and tactile surface is desired for wood, it is advisable to work with carefully selected and coordinated plant-based raw materials. DICTUM walnut wax contains purely natural substances such as walnut oil, beeswax and carnauba wax, which protect and care for the wood. The walnut oil penetrates deep into the wood and the beeswax and carnauba wax protect the wood from dirt and moisture and give it a silky matt surface. Dictum Walnut Wax is completely free of chemical substances, mineral oil derivatives or drying accelerators. The ideal natural care for children’s toys and kitchen utensils, but also for turned parts, solid wood furniture, carvings and handicrafts. For optimum protection, we recommend a treatment with our walnut oil as the first coat and, after drying, one or more coats of our Dictum walnut wax.

Rice bran wax

Rice bran wax, obtained from the rice husk (bran), plays a decisive role in wood surface treatment. In the production of this wax, raw rice oil is first extracted, which is normally used for the manufacture of food and cosmetic products. The oil contains around 4-6% wax, which is separated from the oil using a special process. Obtaining large quantities of this wax is challenging due to the complex process involved.

Rice bran wax is characterized by its high hardness, a melting point of 77-82°C and the possibility of a high gloss level. It acts as a superior binder for oils, especially for oil-wax blends, and shows excellent miscibility. It is also not soluble in water. These properties make it particularly suitable for indoor areas with medium to high traffic.

Rice bran wax (Oryza Sativa Bran Wax) is a superior binder for oils than any other wax and is therefore ideal for oil/wax mixtures. The crude rice oil that is produced for food and cosmetics only contains around 4-6% wax. It is correspondingly costly to obtain large quantities of the wax as a by-product. However, the exceptional combination of high hardness and excellent miscibility make it irreplaceable for wear-resistant ecological surface agents without additives (emulsifiers). Melting point 77-82 °C.

Kerosene wax

Kerosene wax, also known as kerosene fat, is produced as a by-product during the distillation of mineral oil. Further refining steps separate the wax from the kerosene oil. It is characterized by its colourlessness, solvent-free, water resistance, relative softness and melting point at 45°C. It is also chemically inert, which means that it does not interact with wood and metals.

Due to its properties and non-toxicity, kerosene wax can be used in many different ways. The main areas of application are fuel, sealing, care and preservation. It is used, for example, as fuel in candles, oil lamps and barbecue lighters and is also used to soak matches in wood.

Transparent wax for sealing end grain surfaces, for application when turning, for mixing with beeswax, as a preservative for wood and metals and for lubricating sliding joints. Obtained from mineral oil, colorless and odorless, solvent-free and highly water-resistant.

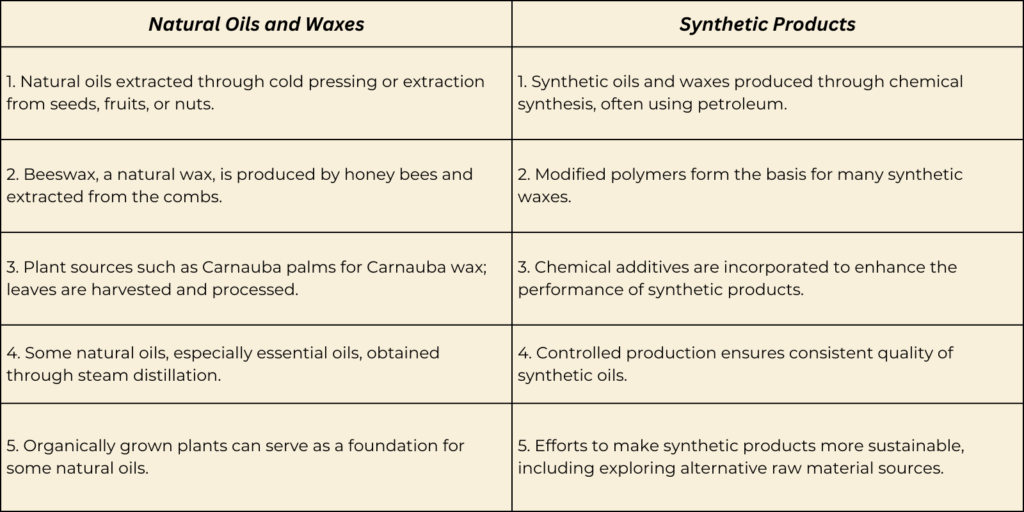

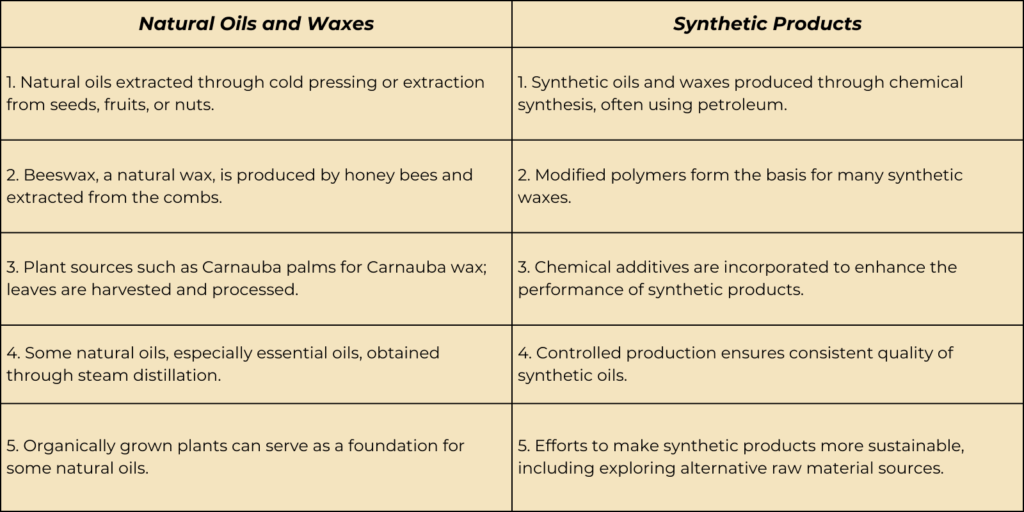

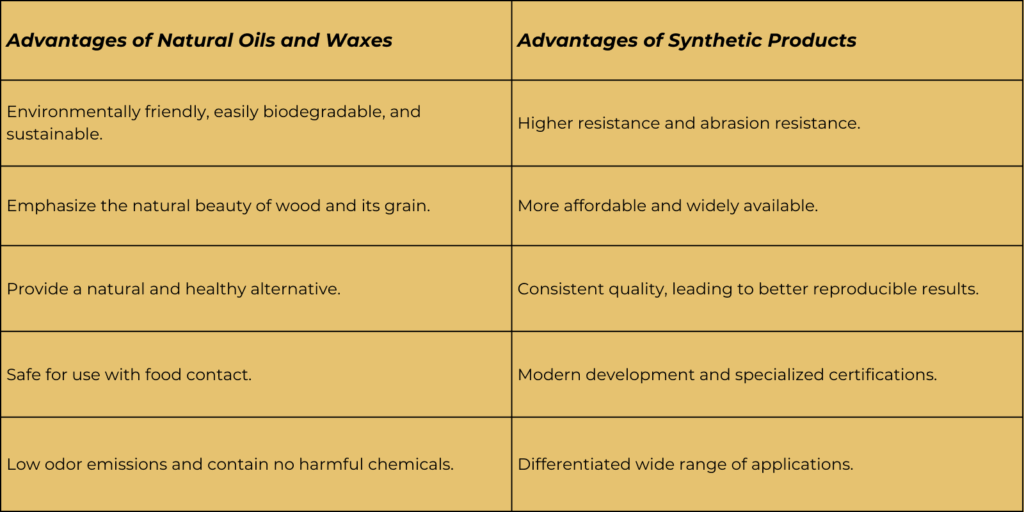

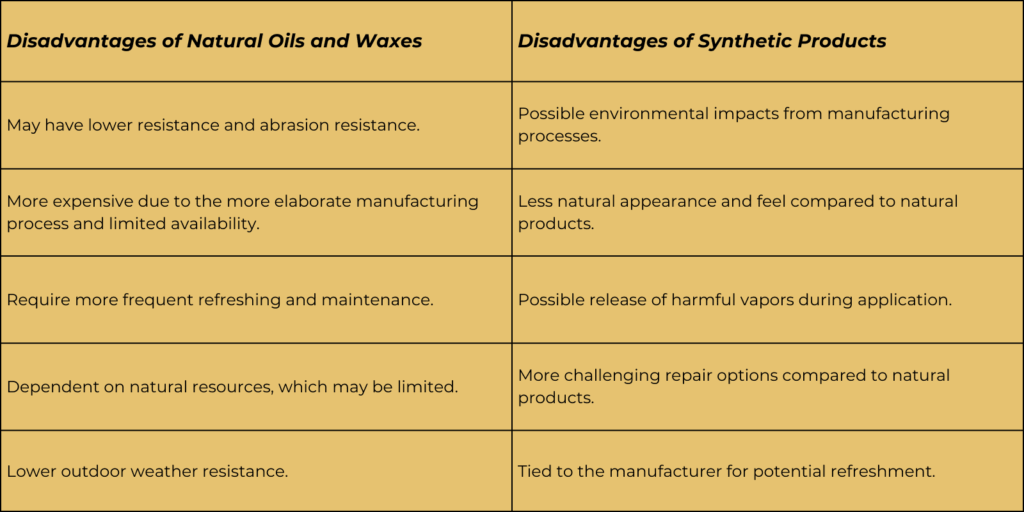

Natural vs. synthetic products

Manufacture

Ingredients

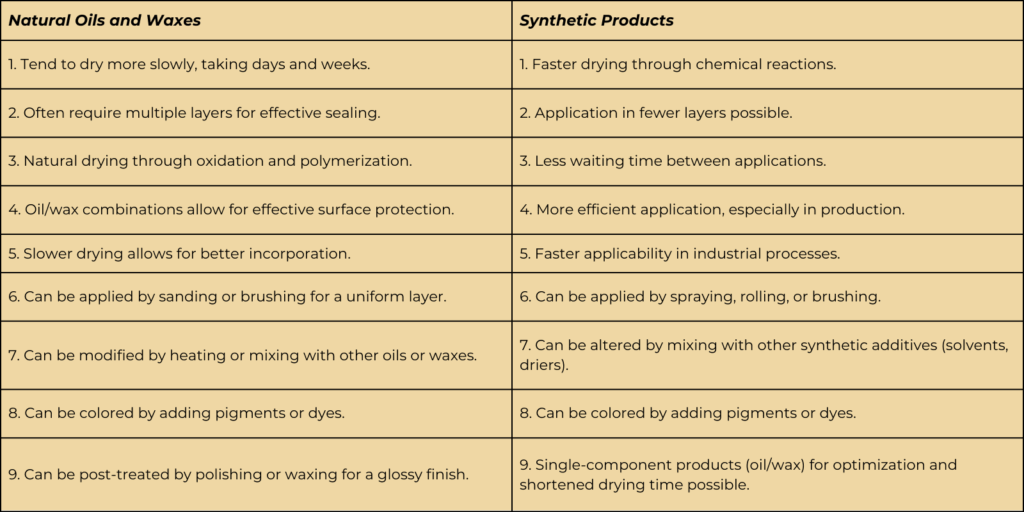

Processing and drying

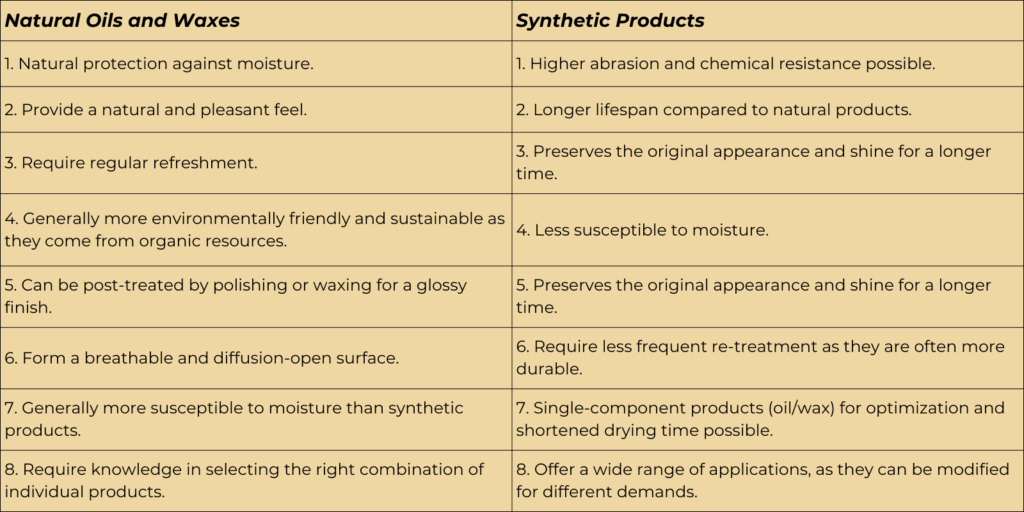

Durability and resistance

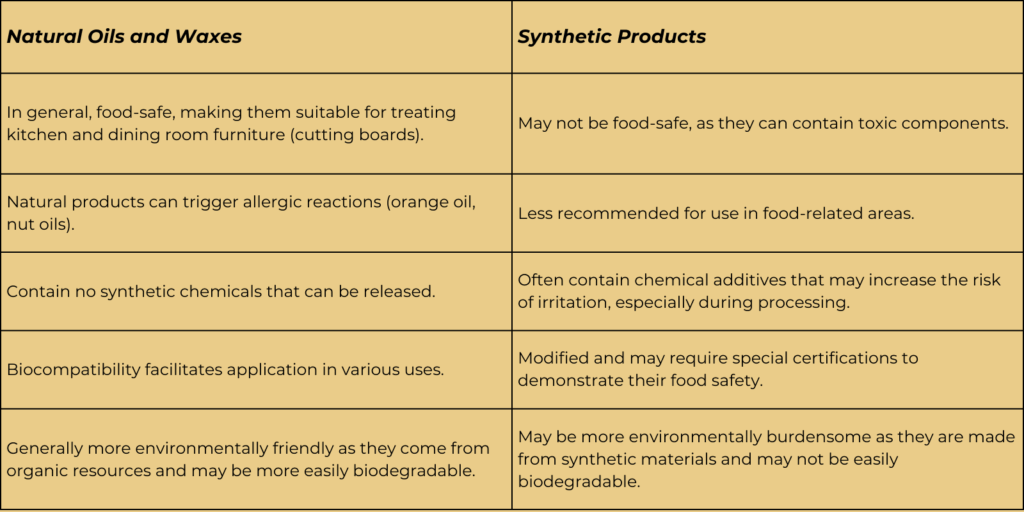

Compatibility and food safety

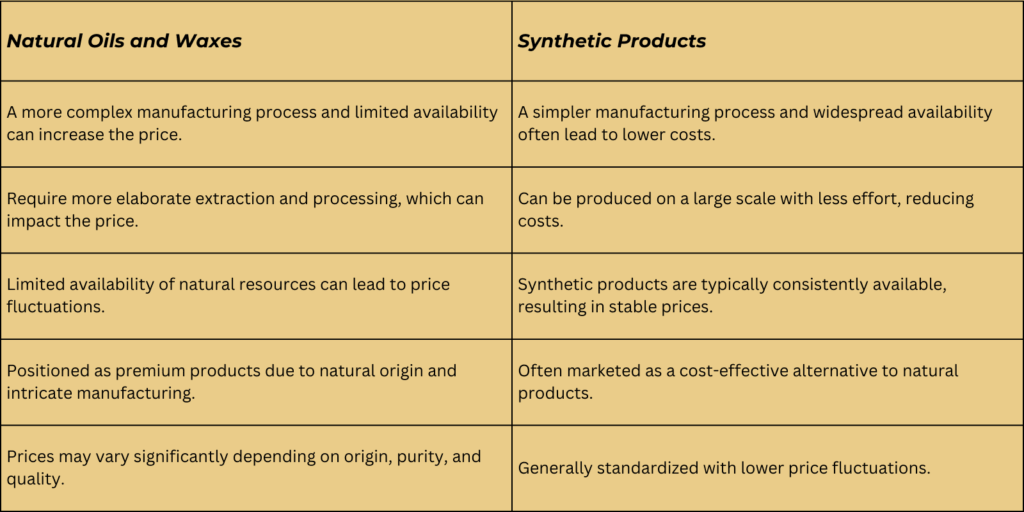

Price differences

Advantages

Disadvantages

FAQ

Why is it important to treat the surfaces of wooden cutting boards?

Hygiene: By sealing the wood, the pore structure is closed, making it more challenging for bacteria and germs to penetrate.

Durability: Surface treatment shields the wood from moisture, discoloration, and wear, extending the lifespan of the cutting board.

Aesthetics: Proper treatment enhances the natural beauty of the wood, making it not only functional but also aesthetically pleasing.

Welche verschiedenen Methoden stehen zur Verfügung, um Holzoberflächen zu behandeln?

Öle: Hierbei werden verschiedene Arten von Ölen verwendet, um das Holz zu nähren und zu schützen.

Wachse: Natürliche oder synthetische Wachse bieten eine zusätzliche Schutzschicht und verleihen dem Holz Glanz.

Lasieren: Durch Lasieren wird eine transparente Farbschicht aufgetragen, die die Holzmaserung betont.

Beizen: Beizen verleiht dem Holz eine farbige, z.T. noch transparente Oberfläche.

Lackieren: Lack bildet eine undurchsichtige Schicht und bietet starken Schutz, kann aber die natürliche Optik verändern.

Epoxydharze: Veredelung mittels Epoxydharzen sorgt für eine robuste, glänzende Oberfläche.

Wie werden Öle unterteilt?

Trocknende Öle: Diese Öle polymerisieren bei Kontakt mit Sauerstoff und härten aus. Dazu gehören: Leinöl, Tungöl,

Nicht trocknende Öle: Diese Öle härten nicht aus, sondern bleiben ölig. Dazu gehören:

Mineralöl, Olivenöl, Rapsöl

Hartöl: Ein Öl, das durch Zugabe von Trockenstoffen schneller aushärtet und einen robusten Schutz bietet.

Hartwachsöle/Hartölwachse: Kombinieren die Eigenschaften von Hartöl und Wachs für zusätzliche Beständigkeit.

Pflegeöle: Mit geringeren Festkörperanteil zur Auffrischung vom Möbel.

Welche Arten von Wachsen eignen sich für die Holzoberflächenbehandlung?

Wachse lassen sich in natürliche und synthetische Wachse unterteilen. Zu den gebräuchlichen natürlichen Wachsen gehören Bienenwachs, Carnaubawachs und Candelillawachs. Die Vielfalt synthetischer Wachse umfasst Esterwachse, Amidwachse, Fischer-Tropsch-Wachse und Polyesterwachse (Weich und Hartwachse in Reperaturkits).

Was sind die Hauptunterschiede zwischen natürlichen und synthetischen Ölen und Wachsen für die Holzoberflächenbehandlung?

Herstellung: Natürliche stammen aus biologischen Quellen, während synthetische chemisch hergestellt werden.

Verträglichkeit und Lebensmittelechtheit: Natürliche Produkte sind oft lebensmittelecht, während synthetische dies meistens nicht sind.

Preisunterschiede: Natürliche Produkte können teurer sein aufgrund aufwändiger Herstellungsprozesse und Verfügbarkeit der Grundstoffe.

Dauerhaftigkeit und Beständigkeit: Synthetische Produkte sind in der Regel widerstandsfähiger, da für entsprechende Verwendung optimiert.

Vorteile und Nachteile: Natürliche bieten natürlichen Glanz, erfordern aber regelmäßige Wartung; synthetische sind langlebiger, könnten jedoch Bedenken hinsichtlich Gesundheit aufwerfen.

Conclusion

The analysis of oils and waxes in this article provides a structured overview of their origin, classification, properties and possible applications. The clear comparison of advantages and disadvantages makes it easier to select the right product for the surface treatment of wooden cutting boards, for example.

The final consideration illustrates the decisive role of the final treatment for wooden cutting boards in terms of hygiene, durability and aesthetics. A suitable surface treatment is essential, especially for furniture that is subject to heavy use, such as chopping boards.

Among the various surface treatment options, including oils and waxes, drying oils such as linseed oil and tung oil in combination with natural waxes are common options for chopping boards.

Manufacturers also offer a variety of oils, waxes and combinations that can be of both natural and synthetic origin.

The choice between natural and synthetic products requires careful consideration of the respective advantages and disadvantages, depending on the specific application. With a certain knowledge of product names and ingredients, the market offers a wide range of optimized and high-quality products.

As in real life, you will never find a product that is 100% perfect in every respect, as there are always pros and cons in terms of ingredients, properties and application. Nevertheless, a healthy ability to compromise and thorough research will enable you to select a suitable product for your individual needs.

After giving you a general overview of oils and waxes in this article, in this article (coming soon) I will focus on the products that are particularly suitable for finishing wooden cutting boards.